GH3351 Monocrystal Silicon Differential Pressure Transmitter

key word:

Hotline:

Description

Introduction

The GH3351 series of intelligent pressure/differential pressure transmiters feature a globally leading high-precision silicon pressure/diferential pressure sensor technology and packaging process, The single-crvstal siliconpressure/differential pressure sensor is located at the top of the metal body, far away from the medium contactsurface, achieving, mechanical and thermal isolation. The glass-sintered integrated sensor lead achieveshigh-strength electrical insulation with the metal substrate, enhancing the flexibility and transient voltage protection of the electronic circuitry. With platinum-level accuracy reaching ±0.05%, it can withstand a maximumone-way overpressure of 25MPa., Boasting excellent static pressure performance, the static pressure error can beoptimally controlled within t0.05%/10MPa, with minimal temperature impact variations, optimally controllableat ±0.04%/10K.

In terms of circuit design, a modular design centered on a microprocessor and assisted by advanced digitaisolation technology is adopted, ensuring the instrument's excellent anti-interference and stability. Communicaton is achieved using the Hart protocol, allowing remote operation through a Hart handheld device or a computer with Hart software to complete measurement information configuration. eanwhile, digital compensationtechnology is employed, and the transmitter is compensated using a built-in temperature sensor, improvingmeasurement accuracy, reducing temperature drift, and possessing long-term stability and high reliability.The most user-friendly design includes infrared wireless settings and a one-button reset function, meeting thesafety operation reguirements in hazardous environments, it provides convenient and guick menu operationsand can complete all parameter settings, comprehensively enhancing the performance of the transmitter.

Features

1.Utilizing Advanced Single-Crystal Silicon PressureSensor Technology and Packaging Processes

2.Modular Design Centered Around a Micropro-cessor with Advanced Digital lsolation Technology

3.Innovative Dual-Compensation Technology forTrue 0.075% High Accuracy

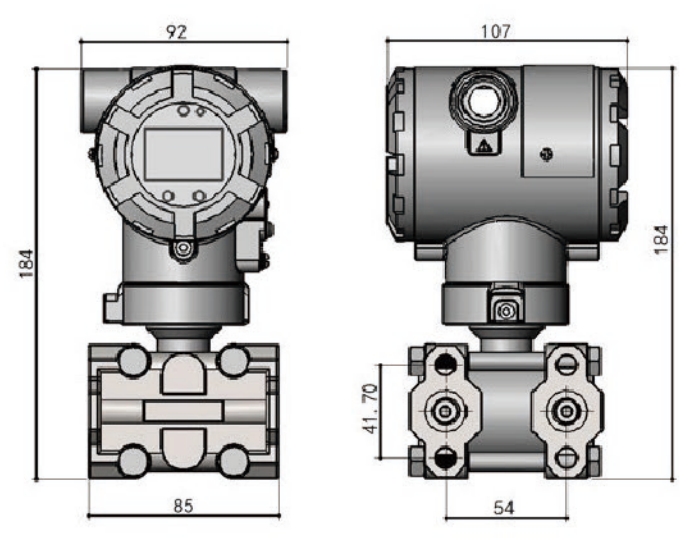

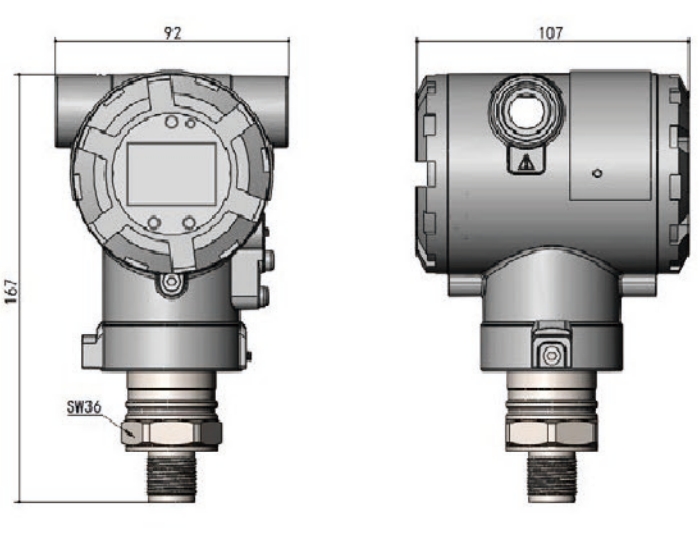

Outline structure(Unit:mm)

|

|

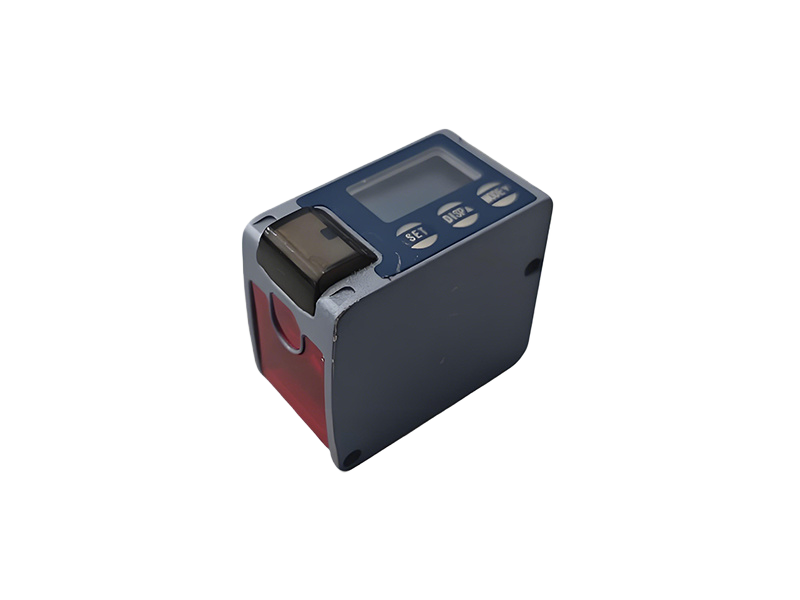

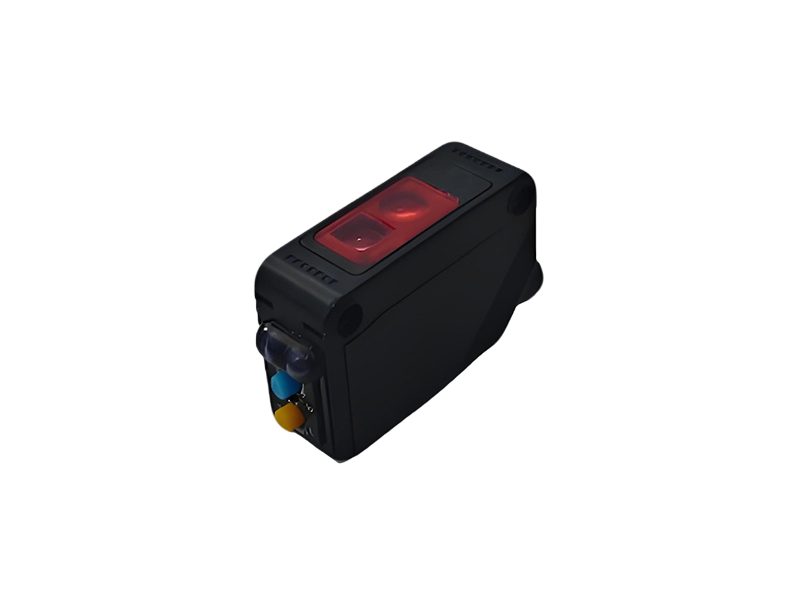

| 1, Differential Pressure Sensor | 2, Pressure Sensor |

Specification

|

Measurement Medium |

Gas,Steam,Liquid |

|

Inaccuracy |

±0.05%、±0.075%、±0.1%(Including Linearity,Return Difference And Repeatability From Zero) |

|

Stability |

±0.1%/3 years |

|

Ambient Temperature Effect |

≤±0.04%URL/10℃ |

|

Static Pressure Efect |

±0.05%/10MPa |

|

Power |

10~36V DC(Recommendation 24V DC) |

|

Power Supply Effect |

±0.001%/10V (10~36V DC),Negligible |

|

Adjustable Range |

If TD>10(TD=Maximum Pressure Range/Regulating Range),then:±(0.075×TD)% |

|

Ambient Temperature |

-40℃~85℃ |

|

Measuring Medium Temperature |

-40℃~120℃ |

|

Storage Temperature |

-40℃~105℃ |

|

Display |

LCD、OLED |

|

Module Temperature Display |

-20℃~70℃(LCD)、 -40℃~80℃(OLED) |

Info Request

For all inquiries, please fill in the form below(* are required) to send us a brief message, and we will get back to you as soon as possible.

Recommended Products